HIKI TEC., JSC has just completed the handover of the Kistler servo pressing system to a German customer - one of the world's leading car gearbox manufacturers. It is known that our customers have headquarters in Germany and manufacturing plants and representative offices around the world. Their products have been trusted by major car manufacturers such as BMW, Chrysler, Mercedes-Benz and many others.

The Servo press is integrated on the customer's production line

Kistler servo press is one of the high quality products we provide to customers. Kistler servo press with high precision, reliability and stability during operation, as well as compatibility with other systems. This helps our customers complete their work in the most efficient and accurate way.

Kistler Servo presses have a wide range of products depending on the customer's problem

Kistler Servo presses have a wide range of products depending on the customer's problem

Benefits of NC Joining Systems

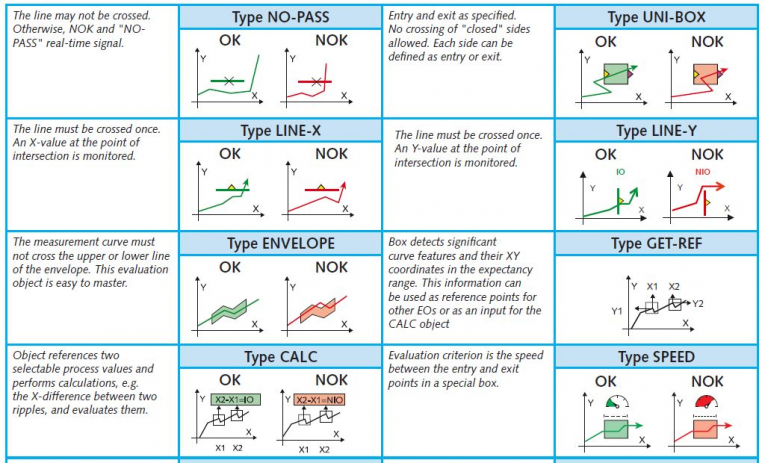

In addition, the servo pressing system also allows customers to set up rules (Evaluation Object-EO) with up to 10 rules on one graph, helping to detect defective products, even the smallest ones, thereby improving performance. product quality, and reduce production costs.

The database is over 120 EOs and allows a maximum of 10 EOs per graph

We are proud to cooperate with our German customers and hope that the Kistler servo pressing system will help them improve production efficiency and achieve success in today's competitive market. At the same time, we are also committed to continuing to provide the best products and services to our customers.

Sincerely thank the trust and cooperation from customers, HIKI TEC., JSC, with the experience and knowledge trained directly from the company, not only provides equipment, but also provides packages. Technical support and after-sales service for customers in Vietnam