Monitoring the structural health of bridges is crucial as it directly impacts safety and longevity.

Dewesoft has developed MEMS-based vibration sensors specifically designed for bridge vibration monitoring. The Dewesoft IOLITE-3xMEMS-8g sensor offers many advantages:

- MEMS technology: This allows the sensor to detect extremely slow vibrations, starting from DC frequency, making it ideal for structural health monitoring.

- Low noise level: Designed for detecting very small vibrations, the sensor has an extremely low noise level of 25 µg/√Hz (or 0.7 µg/√Hz for the high-end version).

- Velocity and displacement measurement: The Dewesoft X software enables the calculation of velocity and displacement values based on vibration signals.

- Perfect ynchronization: These sensors use EtherCAT communication, ensuring signal synchronization at a precision of 1 µs.

- Distributed architecture design: Sensors can be placed up to 50 meters apart using cost-effective CAT6 cables. When combined with optical converters, signal transmission can reach up to 20 km while maintaining synchronization.

- Sensor and DAQ are in one equipment: This reduces costs by 30-40% compared to traditional monitoring solutions.

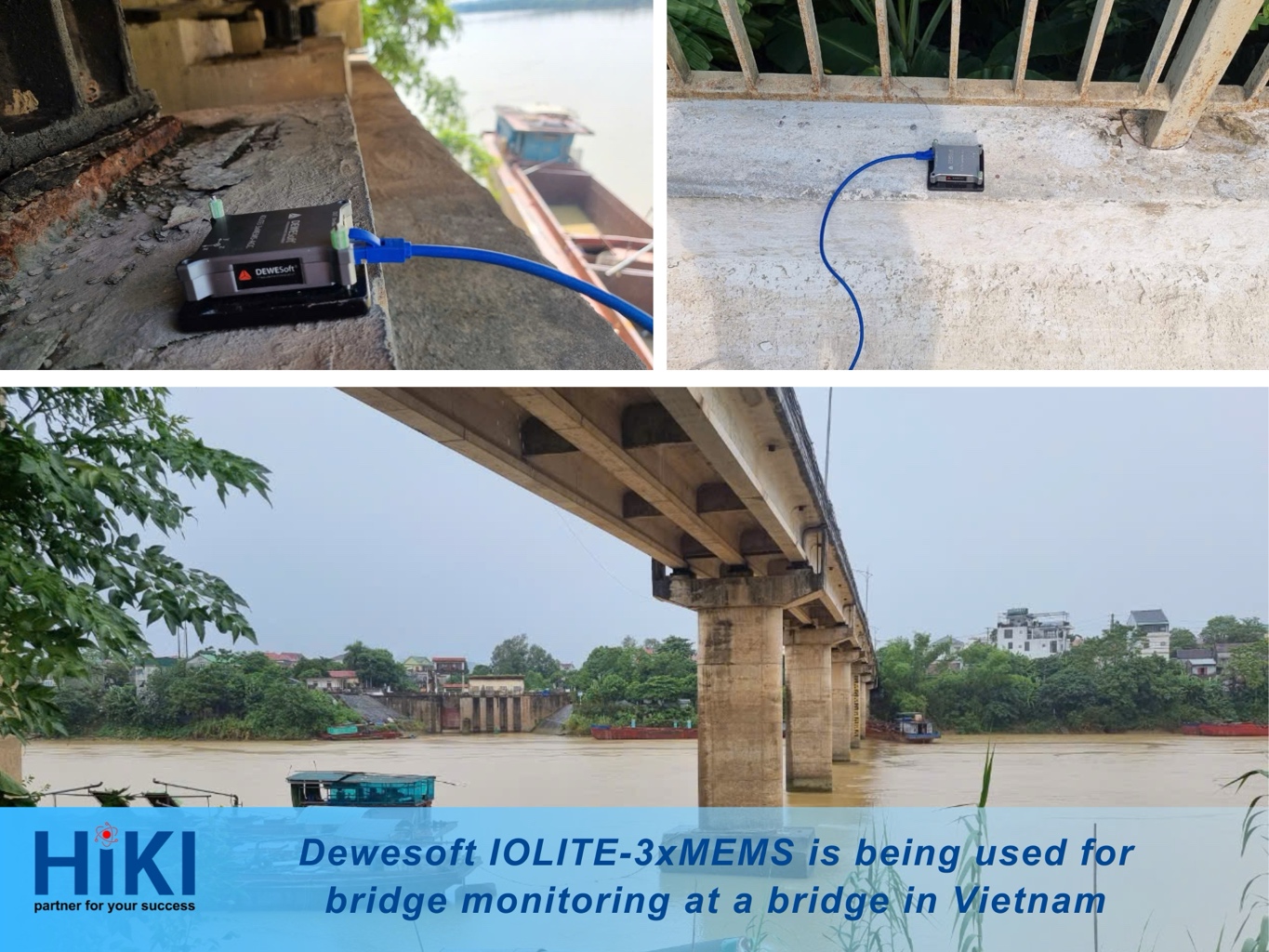

Fig 1: Dewesoft IOLITE-3xMEMs-8g sensor

For more details, please find at: https://hiki-tec.vn/product/bo-xu-ly-tich-hop-cam-bien-rung-type-iolite-3xmems

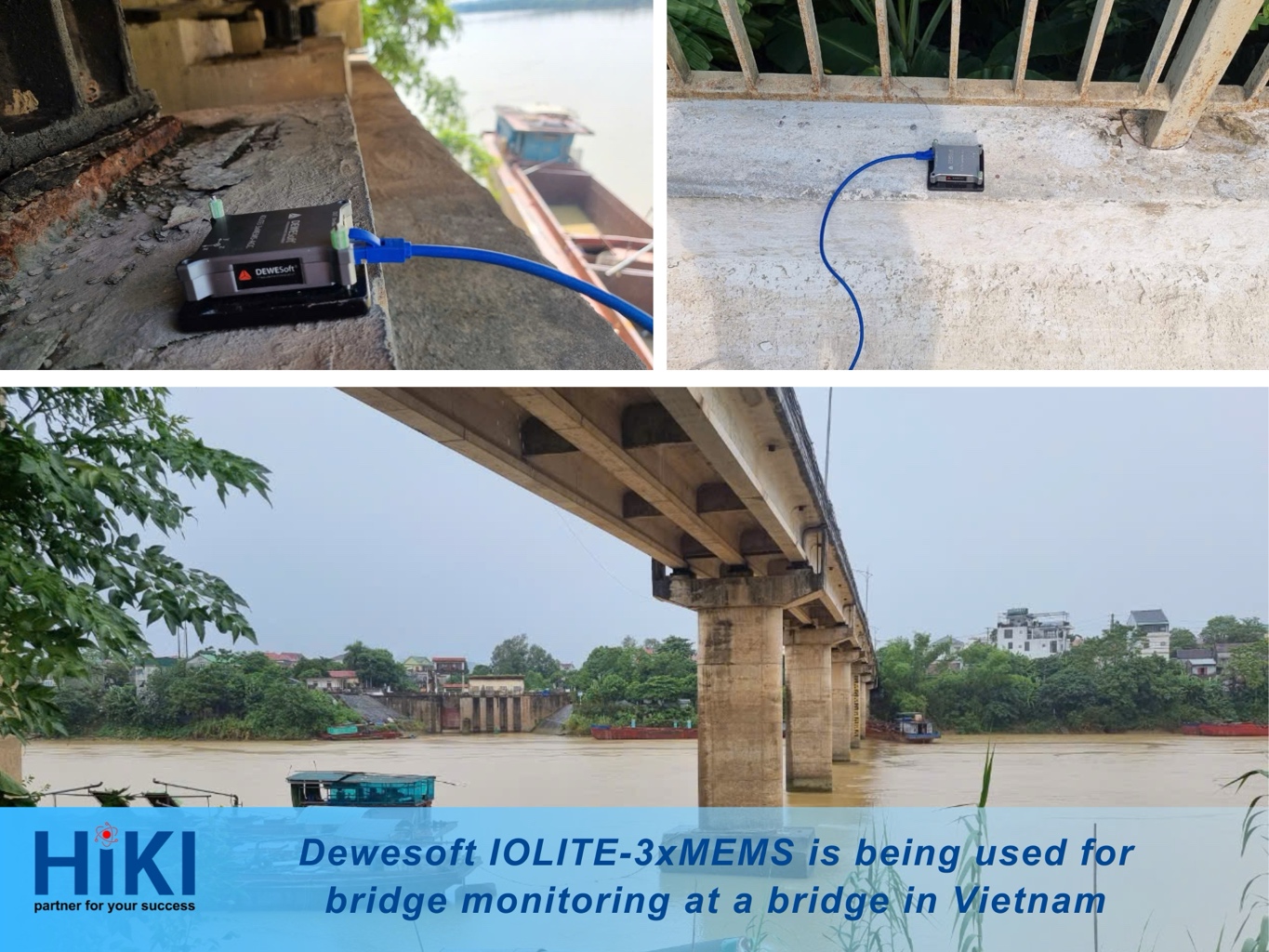

HIKI TEC., JSC is the Dewesoft authorized representative in Vietnam and has supplied the Dewesoft IOLITE-3xMEMS-8g for a bridge monitoring project in Central Vietnam.

Figure 2: The equipment is used for vibration monitoring on a bridge in Central Vietnam.

The system was implemented for vibration monitoring and received positive feedback from the client. Additionally, by using Dewesoft's solution, the client saved 30% in costs compared to traditional monitoring methods.