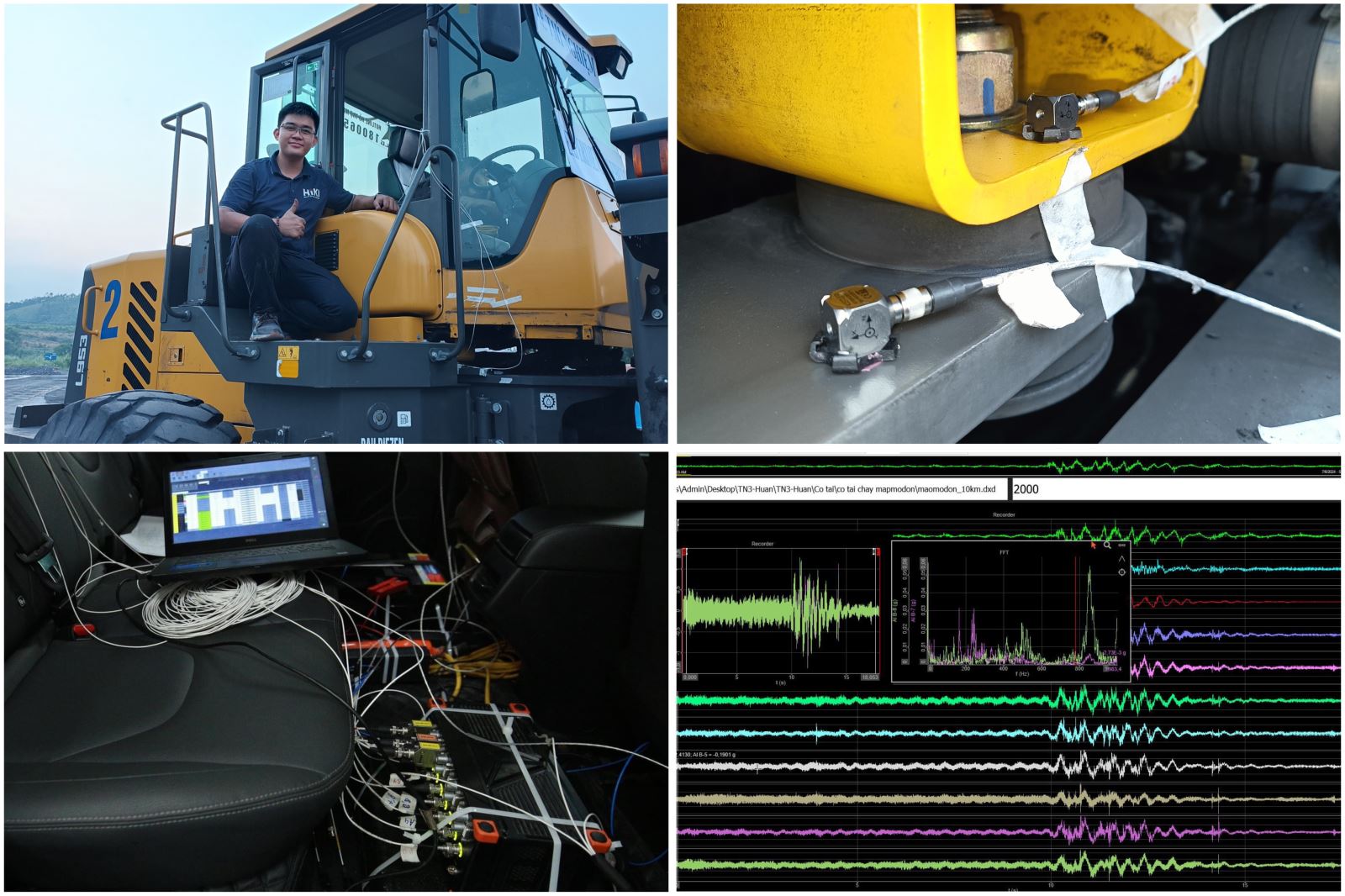

In the context of the increasingly strong development of the automobile industry, the research and application of new technologies to improve product quality is extremely necessary. HIKI TEC., JSC has cooperated with universities to research and deploy vibration measurement solutions on automobiles. The basis for this project is the application of Kistler sensors, known for their high accuracy and reliability, combined with a DAQ data acquisition kit from DEWEsoft.

Vibration in automobiles not only affects the driving quality but also has a great impact on the life of components and systems in the vehicle. Therefore, it is necessary to accurately monitor and analyze vibrations.

Kistler sensors were selected due to their ability to accurately measure vibration parameters with high sensitivity. These sensors not only help collect data quickly but also ensure the accuracy needed for scientific research. Here are some outstanding advantages of Kistler sensors.

High accuracy: Kistler sensors provide accurate and detailed data, helping engineers easily identify and fix vibration problems.

Durability and reliability: These sensors are designed to operate stably in harsh conditions, ensuring that measurement results are not affected by the environment.

Wide application: The solution can be applied to many different types of vehicles, from conventional cars to electric and hybrid vehicles.

DEWESoft is one of the leading brands in the field of data acquisition and analysis, providing powerful solutions for signal measurement and analysis. DEWESoft data acquisition features multi-channel data acquisition, high synchronization capabilities and a user-friendly interface. At the same time, DEWESoft supports a wide range of sensors, allowing users to easily integrate and manage devices.

When combining Kistler sensors with DEWESoft data acquisition, users can enjoy the best of both worlds. Kistler sensors provide measurement data with outstanding accuracy, while DEWESoft ensures that this data is collected and analyzed efficiently and reliably. This integration enables flexible and rapid product development and development, thereby improving the quality and performance of engineering applications.

Participating in this project, lecturers and students from the university sector will have the opportunity to apply theory to practice, conduct systematic research and come up with new solutions. This not only contributes to improving students' skills but also promotes creativity and innovation in scientific research.

Measurements were conducted on various types of vehicles to assess the vibration levels under actual operating conditions. The collected data will help researchers analyze and propose corrective measures, while optimizing designs to improve vehicle stability and safety.

HIKI TEC., JSC believes that this cooperation will bring many benefits not only to the company and universities, but also to the entire automotive industry in Vietnam. The application of modern vibration measurement technology will contribute to improving product quality, meeting the increasingly high demands of domestic and foreign markets.

In the future, HIKI TEC., JSC hopes to continue to expand cooperation with many other universities and research organizations, aiming to provide more advanced technological solutions, not only in the automotive field but also in many other fields.