Enhancing product quality based on international acoustic measurement standards

06.01.2026

The acoustic measurement solution implemented by HIKI is based on a Class 1 sound level measurement system compliant with IEC 61672, meeting stringent requirements for accuracy and reliability in acoustic metrology. The system enables comprehensive real-time sound pressure level measurements while supporting frequency spectrum analysis with octave and one-third-octave bands, as well as post-processing with finer spectral resolution when required.

SurTec Vietnam Integrates Kistler’s Precision Friction Analysis

23.12.2025

HIKI TEC is proud to announce the successful technology transfer of the Kistler ANALYSE system to SurTec Vietnam. This project highlights HIKI TEC’s role as the strategic bridge between Kistler’s world-class measurement technology and the evolving needs of the surface treatment industry in Southeast Asia.

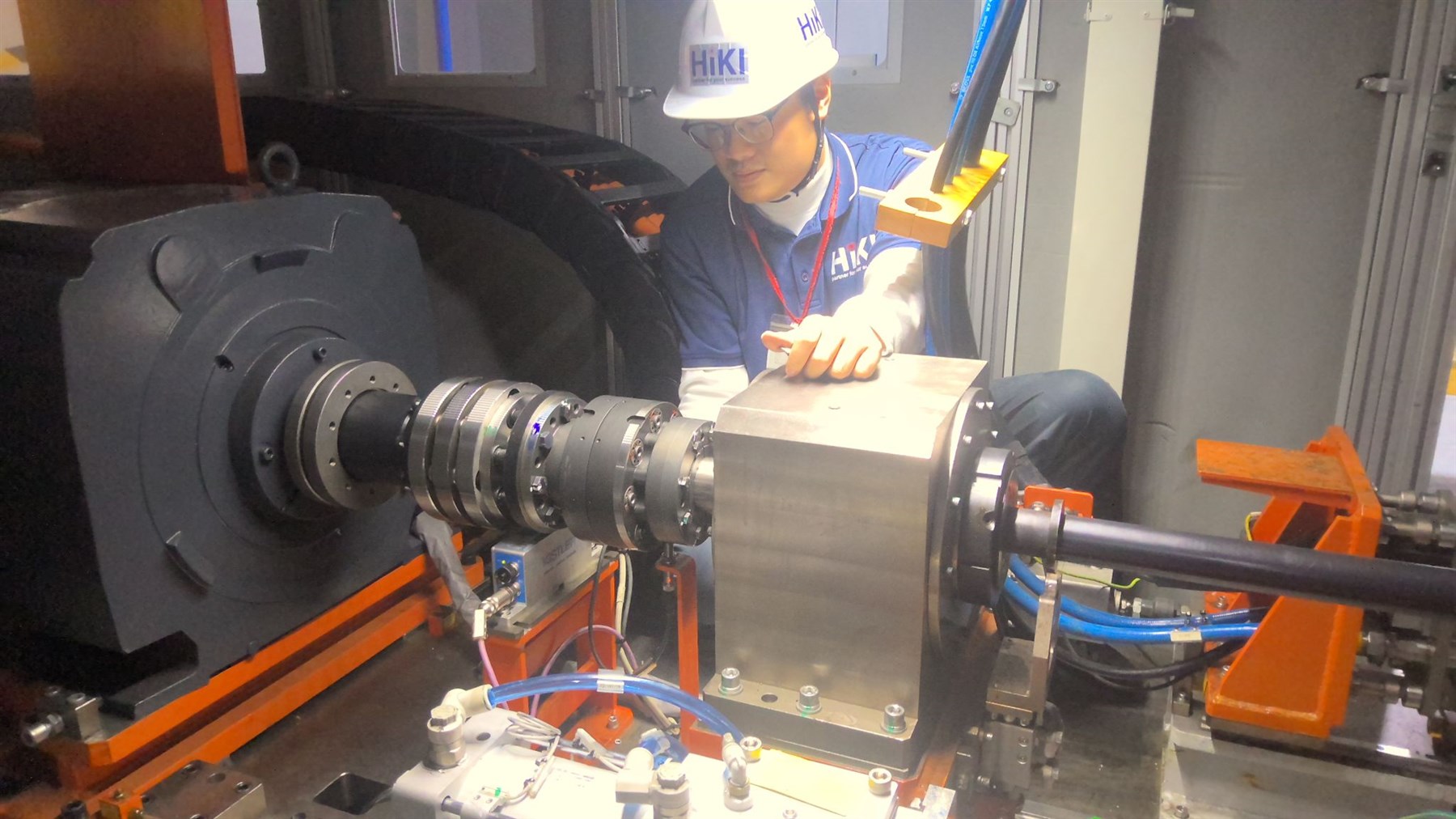

KiTorque 4552 provided by HIKI for Electric Motor Test System

16.12.2025

The Kistler KiTorque 4552x torque sensor has been developed to meet these requirements, providing an integrated solution for torque, speed, and angle measurement within a single sensor. The sensor is well suited for both process monitoring in production environments and high-precision testing applications in R&D.

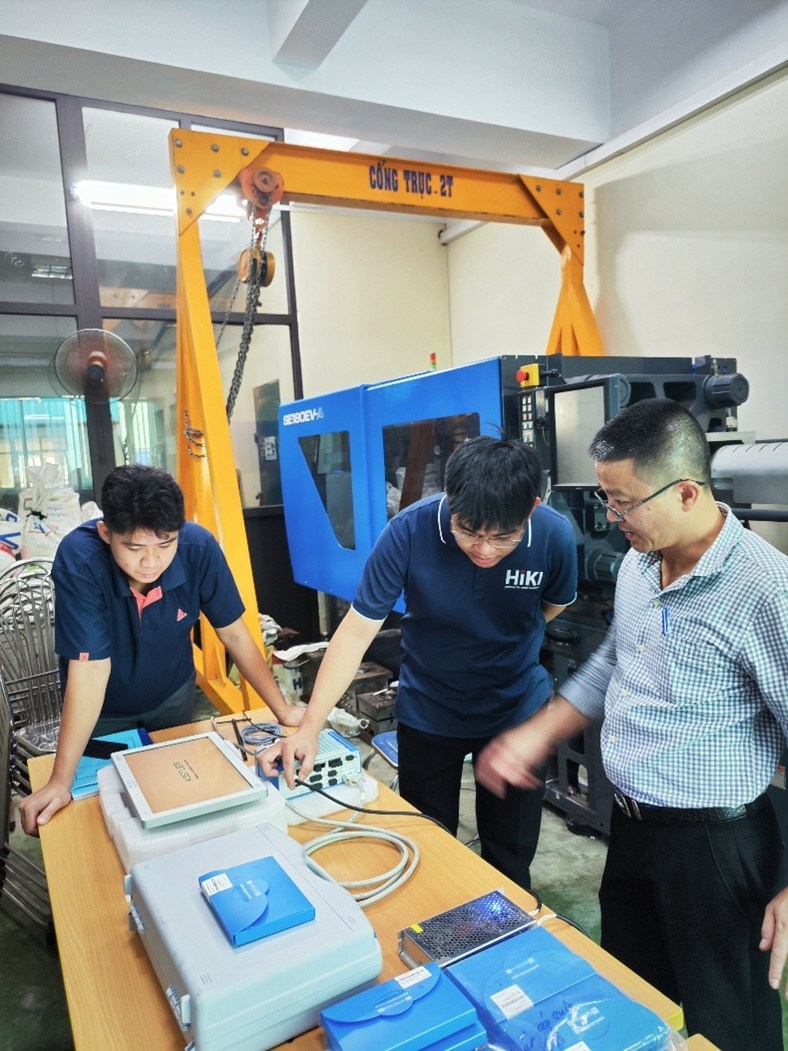

HIKI commissions Kistler injection molding process monitoring system for a university

07.11.2025

HIKI Tec., JSC has recently completed the technology handover and training of a Kistler mold Cavity Pressure Measurement System (CPS) for a leading technical university in Hanoi. The project aims to enhance process efficiency and improve the quality of molded plastic parts for high-tech applications in the Automotive and Aerospace sectors.

VINFAST & HYUNDAI KEFICO TRUSTS SOLUTIONS AND SERVICES PROVIDED BY HIKI

29.10.2025

The force–displacement monitoring system provided by HIKI TEC., JSC is ideally suited for industrial production lines in automotive, electronics, and semiconductor sectors—applications requiring the highest levels of accuracy and reliability. In precision joining and assembly operations, force–displacement monitoring enables early detection of defective components, allowing them to be automatically sorted out directly on the production line

Delivery of measuring instrument to a semiconductor customer

09.05.2025

As a key manufacturing center of Samsung Group, Samsung Electro-Mechanics Vietnam (SEMV) specializes in manufacturing and assembling high-density interconnected printed circuit boards (HDI) (including FPCB and Main board) and components and spare parts such as camera modules, etc., supplying the global market. Operating in this high-tech field requires SEMV to maintain a manufacturing environment where absolute precision and uncompromising quality control are the core foundation.

Molex Vietnam trusts solutions and services provided by HIKI

28.03.2025

Molex is a global leader in manufacturing and providing electronic connectivity solutions, founded in 1938 in the United States. With operations spanning over 40 countries, Molex delivers innovative products and services across multiple industries.

Delivery of High-Speed DAQ System to R&D customer

02.03.2025

HIKI TEC., JSC, with over 10 years of experience in the field of TEST & MEASUREMENT, has been chosen by customer in the research and development (R&D) sector to provide a high-speed data acquisition (DAQ) solution that meets specific requirements: