9.08.2022

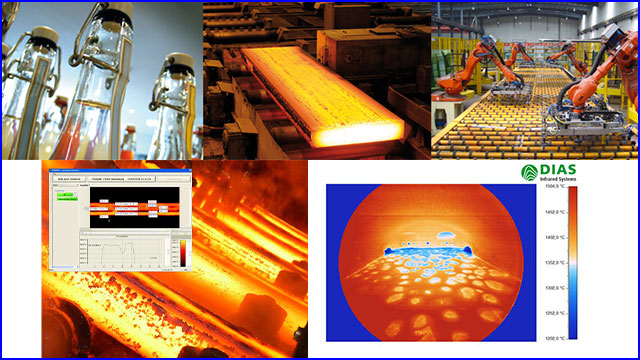

Non-contact temperature measurement uses infrared cameras that measure temperature by zone / line (Infrared cameras PYROVIEW / Infrared line cameras PYROLINE) or use point temperature sensors (Pyrometers PYROSPOT)

Benefits for customers:

Save cost and time through fast and non-contact temperature measurement

No interruption in the production process

Increase process reliability with immediate calibration

Quality control by real-time process monitoring

Optimize heating and cooling processes

Improve the quality of the final product

Extend service life for heat-resistant materials

Increased economy by reducing wear and tear

Recognizing the danger caused by possible cracks or punctures.

Metallurgical industry

Measuring non-contact temperatures with metals, especially between 100°C and 3000°C, is crucial. This range includes low and high temperatures. Therefore, the fields of application of non-contact infrared temperature measurement technology in the metal industry are diverse.

Temperature control in the stages of casting, forging, heat treatment ensures uniformity in production processes.

The purity level of liquid steel released from furnaces or electric furnaces must be monitored for slag content with increasing requirements, which is also applicable when transferring steel into casting dies.

Using PYROSPOT thermometers and PYROVIEW infrared cameras, customers can ensure accurate process temperatures during the process and closely monitor the temperature distribution in the surrounding area.

By non-contact temperature measurement on the glass surface, customers can detect cracks, thicknesses, thin spots or bran pimples during glass production. Besides, customers can control the temperature of the glass to optimize the heating and cooling process: the temperature change on the glass surface when cooling, cooling speed. Especially heat control in glass bending ovens.

Typically, the use of PYROLINE infrared cameras in monitoring the production of floor coverings (linoleum). These cameras enable fast, non-contact and high-precision temperature measurements in the temperature range from 100°C to 200°C.

Automation in the food industries means increasing productivity through saving time and personnel. In particular, the decisive factor for success is that product quality is always guaranteed to be uniform.

Comprehensive thermal monitoring solution with signal synchronization of up to 8 external side cameras from PYROSOFT AutomationSC software.

DIAS's automatic and continuous monitoring systems are equipped with highly sensitive temperature cameras that can detect early signs of fire and issue warnings on the display screen. The system is widely used in paper mills, wood processing, warehouses with flammable materials, recycling warehouses ,...

Solar Energy Industry

Monitoring of combustion chambers, furnaces

Temperature monitoring in cement plants

Research and development in semiconductor technology, biotechnology

Bibliographic references: