-

Products

- Sensors

- Equiment & systems

- Other systems

- Solutions

- Services

- News

- Video

- Knowledge Center

- About us

21.01.2022

On January 21, 2022, HIKI TEC., JSC and Kistler organized an online seminar with Hanoi University of Industry on plastic major. The seminar was attended by Kistler’s leading experts in the field of plastic molding, as well as Assoc. Prof. Dr. Hoang Tien Dung – In charge of the Faculty of Mechanical Engineering and teachers and lecturers in the department.

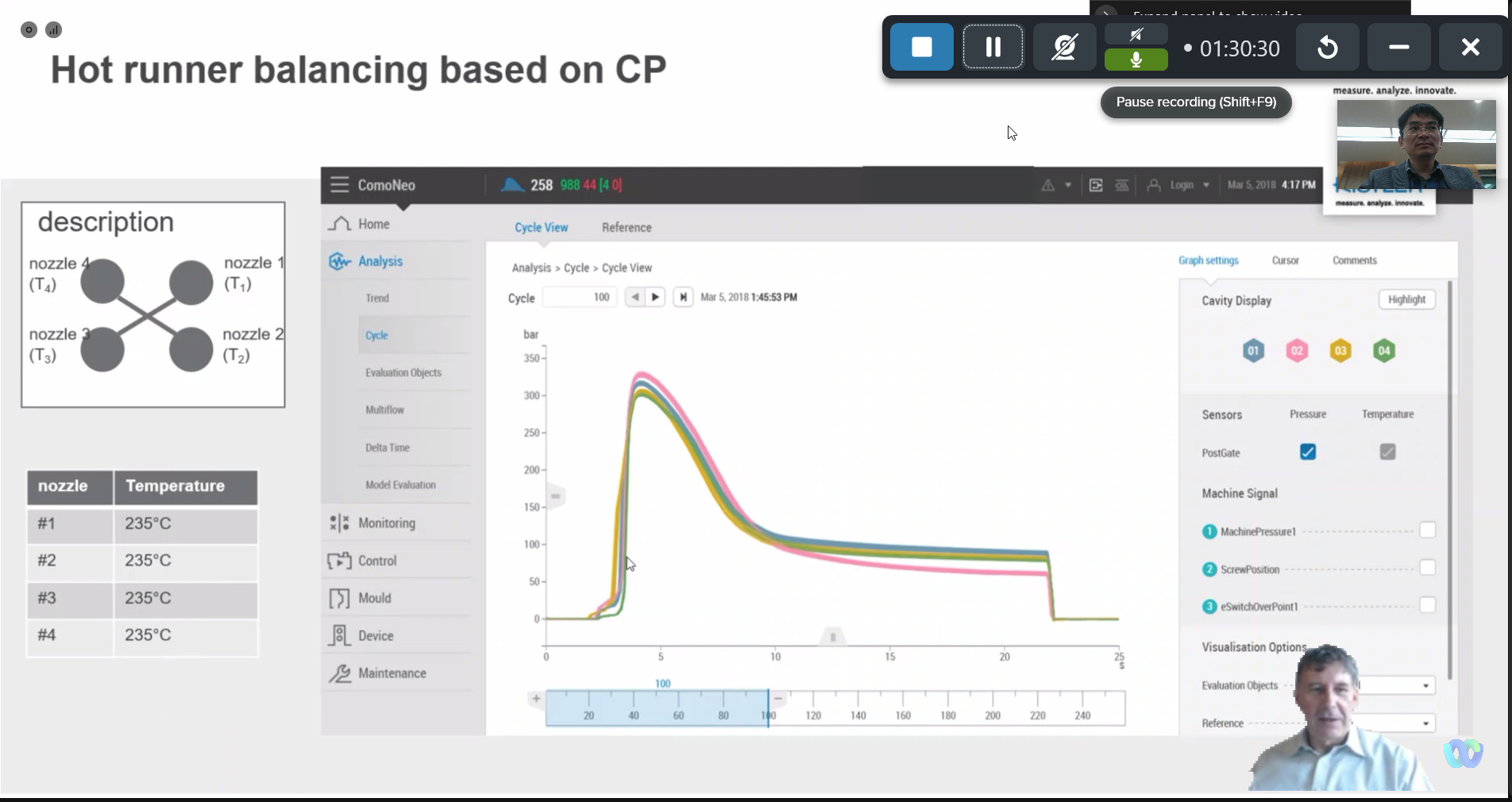

Mr. Robert Vaculik – Kistler’s expert introduced about the pressure measurement system Cavity – ComoNeo to the invited guests. The system uses piezoelectic pressure sensors mounted directly at Cavity. From the signals from the sensor, the controller redraws the entire graph of the plastic molding process and displays it visually for the user.

The Cavity – ComoNeo pressure measurement system allows a closed process: from measuring, monitoring, and controlling to the transparency of all production data. By monitoring the pressure and temperature of Cavity in the plastic molding process, we can detect defective products in the production stages.. Defective products such as: Short-Shots (lack of plastic), Sink marks (surface deformation), Flashes (deformation), Shrinkage & warpage (warping),…

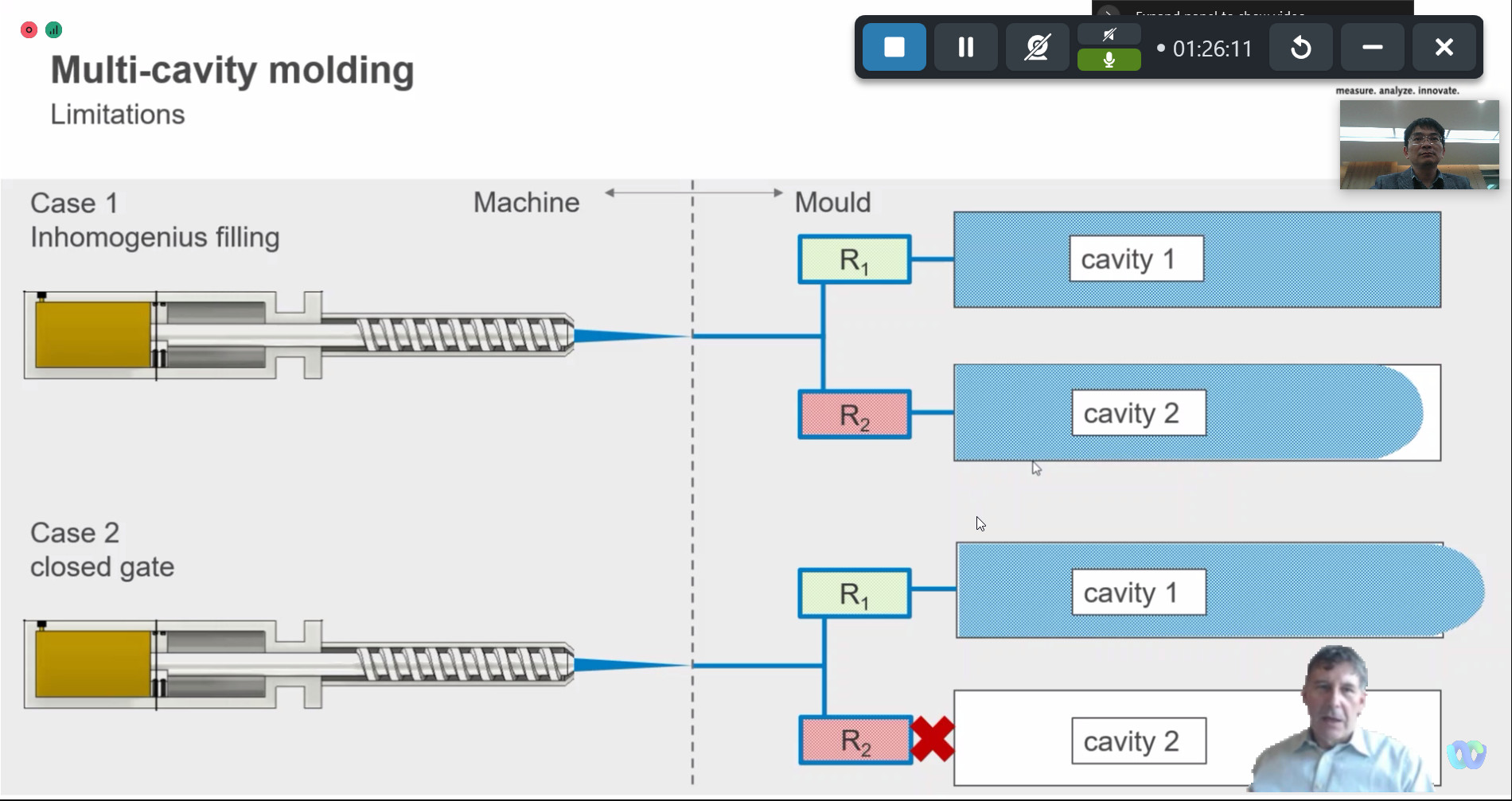

In addition, the ComoNeo system can also allow control of the pressing process and the hot runner system helps to ensure the balance of the Cavities – regardless of the type of machine, mold and peripherals being used. .

In addition, the ComoNeo system can also allow control of the pressing process and the hot runner system helps to ensure the balance of the Cavities – regardless of the type of machine, mold and peripherals being used. .

Advantages of ComoNeo cavity pressure monitoring system: compact, rugged design; simple and effective connection technology; Simple system easy to use, wide range of products.

More information at: Cavity pressure measurement.

Contact us at: +84 986 995 815.

We are here to assist you, make a consultation appointment and our support team will contact you directly:

Wishing you a lot of health, happiness and success!